Molds for production of double-sided fence systems with natural stone, brick and wood imitation

Today‘s market of decorative concrete fences is filled mainly with products, which have been manufactured in hard molds, which frankly speaking, is more suitable for installation around industrial areas or such. Decorating such fences with standard facade paint also looks quite ridiculous.

Our company is offering a totally different concept of decorative concrete fence systems. MAGICRETE ® is the only European producer of flexible molds for manufacturing of DOUBLE SIDED fences. Thanks to the flexible insert, which is used in fence molds, the texture of fence elements looks identical to the natural material – whether it’s the green slate from the far regions of Czech Republic or old barn wood.

Texture of product, which has been manufactured in a hard mold looks very simple and does not have decorative properties. There are two reasons for it – plastic (glass reinforced, laminate, polypropylene, etc.) is simply not suitable for casting concrete products with a deep structure and thus not able to pass on the detailed texture of a natural material. Another reason is that most manufacturers are offering a single texture for a panel, which is constantly repeating within 1 fence section. For example, our DWL fence series has a height of 3 m, width of 2,3 meters and does not have a SINGLE REPEATING element – all the elements are unique.

Below you can see for yourself the quality of MAGICRETE fence systems compared to products, which have been manufactured in a hard (plastic) mold.

Panels from hard molds (image A) have only 1 texture type, which is repeated on all the panels. MAGICRETE products (image B) have 7 different textures, which is why you can hardly find any repeating elements.

Texture of panels, which have been manufactured in plastic molds (image A) are very primitive and can be barely compared to natural stone. Surface of panels is cropped with a huge amount of pores, which is due to technical aspects of production in hard molds that cannot be avoided. Texture of MAGICRETE panels (image B) is extremely detailed and the surface is almost identical to natural stone chip.

Fence slopes from a hard mold (image A) are simple concrete pillars, MAGICRETE fence slopes (image B) have a structure, which is identical to panels.

The main structural difference of MAGICRETE fence system is that our system is DOUBLE SIDED – both panels and slopes have texture on front and rear sides. Rear side of panels, which were manufactured in hard forms is plain concrete.

Service life of molds is a very important factor - our molds can withstand up to 3000 production cycles, which is practically 10 years of service. Hard molds need to be replaced after 200-300 cycles.

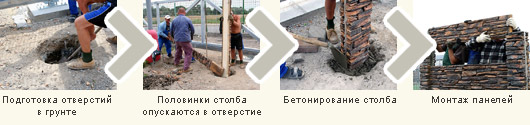

Installation of panel fences is quite simple, they don’t require a massive concrete base and single element weight of up to 90 kg means that you will not require specialized equipment to carry out installation.

Production of MAGICRETE fence system requires only a basic fitting of production facility – besides the molds you will require a concrete mixer, vibrating table, electric lift for manipulation (can be substituted by a beam crane), technical trolleys and hand instrument.

We would like to point out the cassette construction of our forms – it enables you to increase the output of production, as well as to decrease the inputs of man-hours, thus leading to overall decrease of production costs.

| Cassete mold | Concrete mixer | |

Vibrating table | Electric forklift | |

| Stacked cassete molds | Stacking molds with forklift |